Sloped Trench Drain System - 39.37" Channel - ACO K100

FREE SHIPPING

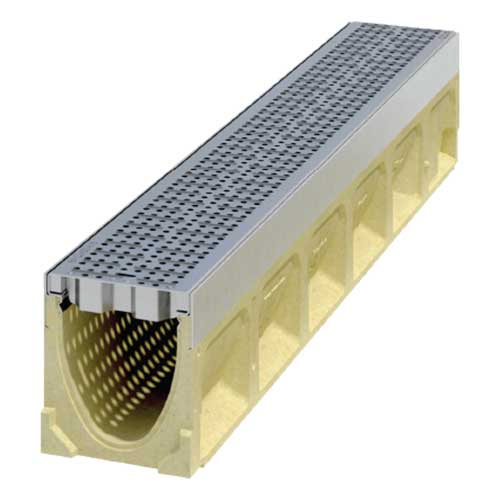

The ACO K100 Sloped Trench Drain System is a high-performance modular drainage solution designed to handle water management with efficiency and reliability. Featuring a 4-inch internal width and a continuous built-in slope of up to 130 feet, this system promotes smooth water flow and minimizes pooling.

Built with robust galvanized steel or stainless steel edge rails, it delivers long-lasting durability in demanding environments. The advanced boltless locking mechanisms, DrainLok and QuickLok®, make grate installation and removal fast and simple, while anti-shunt lugs and numbered channels ensure accurate alignment and secure grate placement.

Offering a wide range of grate styles—mesh, slotted, perforated, and ductile iron—rated up to Load Class E, the Sloped Trench Drain System adapts to a variety of applications, from commercial to heavy-duty industrial projects.

System Selection:

-

Scroll down to select your system components. Multiple channel units are connected together and then paired with accessories such as catch basins and grates.

Please Use the Order Form Below to Order ▼